As China’s electric vehicle sales have increased dramatically, a forecast report says the lithium-ion power battery market is entering a golden period, and by 2017, the power battery industry will skyrocket to 400% of its current size. Under such a leapfrogging scale growth, the quality of the battery has become an unavoidable technical point. Recently, Beijing issued a document to adjust the vehicle and power battery warranty, in which the power battery and other key components to provide no less than 5 years or 100,000 km of warranty, adjusted to provide no less than 8 years or 120,000 km of warranty.

China’s power battery life extension technology breakthrough becomes the key

Shanghai, like Beijing, as the leading demonstration city for the promotion of new energy vehicles, is also considering to improve the service life of the power battery, the power battery can generally run for 5 years and 100,000 kilometers. How to break through the technical bottlenecks and extend the service life of the battery is the common problem faced by all battery manufacturers nowadays.

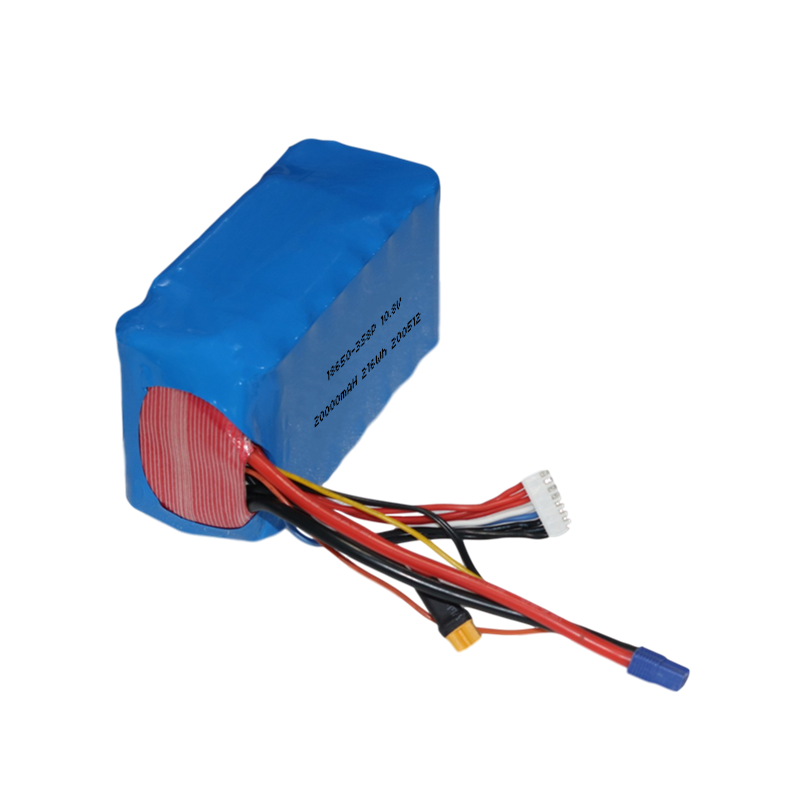

The bottleneck of electric cars lies in the battery, and only if the battery power problem is solved, all other problems can be solved. In the current technical conditions, change the charging mode of the power battery is a good choice to extend the life of the battery. Industry insiders pointed out that the current propaganda 8-year warranty, in fact, may not be able to achieve. Automobile power battery in the production process due to differences in the production process, there are some differences in the performance of the battery pack battery monomer. With the passage of time, the differences between the cells in the battery pack will gradually expand, which will eventually affect the performance of the battery and cause rapid deterioration of the battery performance. Different charging methods are important factors affecting the performance and service life of single lithium-ion batteries, and the appropriate charging method can not only maximize the battery capacity, but also prolong the battery life.

China’s power battery life extension technology breakthrough becomes the key

Long charging time, short mileage is the current electric car is much criticized. To take a large rate of fast-charging although solving the problem of long charging time, but in fact seriously affect the service life of lithium batteries. The constant pursuit of fast charging, large rate charging, prone to high temperature, overcharging and other abnormalities and even lead to danger. Take the “first soft then strong” charging mode, under the battery can withstand the voltage, current, and monitor the environment, temperature, temperature difference, active maintenance of battery health, will help to prolong battery life and reduce safety risks.

Charging methods are one way to extend battery life, but they are not a fundamental solution. The improvement of battery life and stability still needs to make a breakthrough from technology. In view of the current situation in China, power batteries from the production technology level, our battery enterprises are behind the world level in terms of production and research and development capabilities. The output of new energy vehicles reached 76,000 units, an increase of 2.5 times year-on-year. There is a large number of shortages in the supporting power battery for new energy vehicles, coupled with the low barriers in the power battery industry, leading to a large number of battery enterprises with low technology content to put into production, finally resulting in the situation of domestic low-end battery excess capacity and high-end battery market gaps. In addition, the lower technology content of the battery energy density is low, which affects the mileage of new energy vehicles, if the production of the same capacity of the battery, China’s battery weight will exceed the weight of Japanese and Korean enterprises battery, which in turn will affect the lightweight development of new energy vehicles.

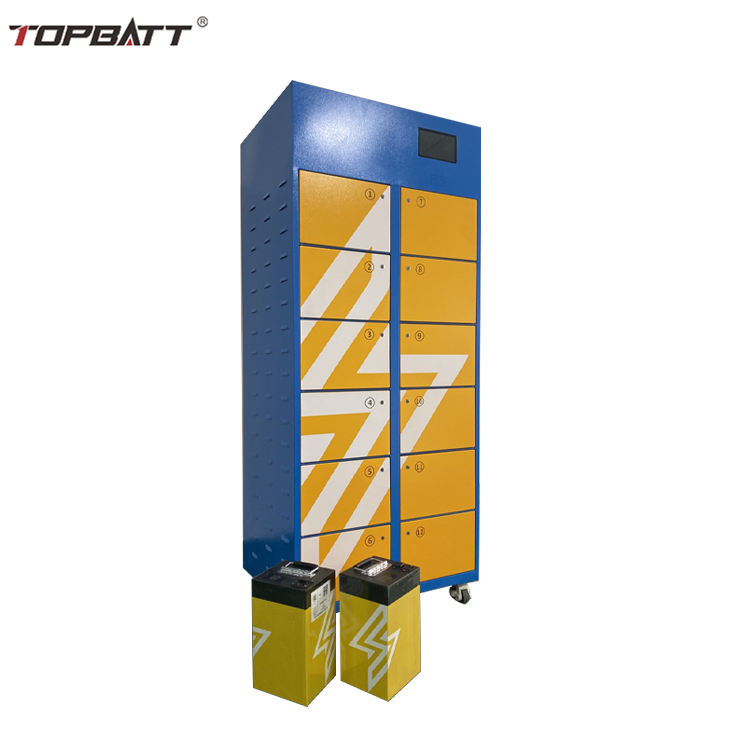

In addition, the lack of a unified production standard in China’s battery industry, the battery enterprises produce power batteries of poor versatility, unable to achieve standardization, large-scale production, but also increased the workload of battery design. Due to the lack of unified industry standards, the charging and discharging performance of the batteries produced by various enterprises is very different. The lack of standards upstream and the inability to standardize has directly led to the charging stations showing large differences and has become one of the reasons for the difficulty of charging. A unified battery standard will help standardize the battery industry, help save manpower and material costs, and put more resources into the battery research and development and production process improvement.

China’s power battery life extension technology breakthrough becomes the key

On the one hand, the country’s support for electric vehicles continues to increase, lithium-ion battery power to face a rare development opportunity. On the other side but due to the battery range, safety and other obstacles have been slow to breakthrough. Compared with the international, China has many problems in the electric vehicle power battery. On the one hand, China’s advanced materials and mechanism research is poor, battery structure design technology is less advanced, on the other hand, the degree of automation is low, precision process development capacity is also weak. The battery system is not just a matter of assembling the monomers; it is actually a very complex technology. In addition, the supply of high-end materials required for batteries is still insufficient, consistency, yield, safety, reliability, product performance can not fully meet market requirements, the overall innovation capacity of enterprises is not strong, and the advantage of production capacity is not enough.